by Serge Popovich | Dec 10, 2020 | News

10th December 2020

Pulford Air & Gas has ordered more HQ structures with heat protection and due to volume and convenience the project was applied at C-COAT facilities and delivered to Pulford for assembly and shipment to Western Australia upon. The logistics and timing was of concern and delivered as planned and agreed

by Serge Popovich | Sep 12, 2020 | News

The sample of 4.5mm fibre-cement board coated with C-COAT was tested to strict Australian Fire standard AS1530.3 and passed with excellence. During this period we also tested our Intumescent coating material which is now complimenting our Thermal Insulating Systems, Both product have shown amazing performance and results.

by Serge Popovich | Dec 6, 2019 | News

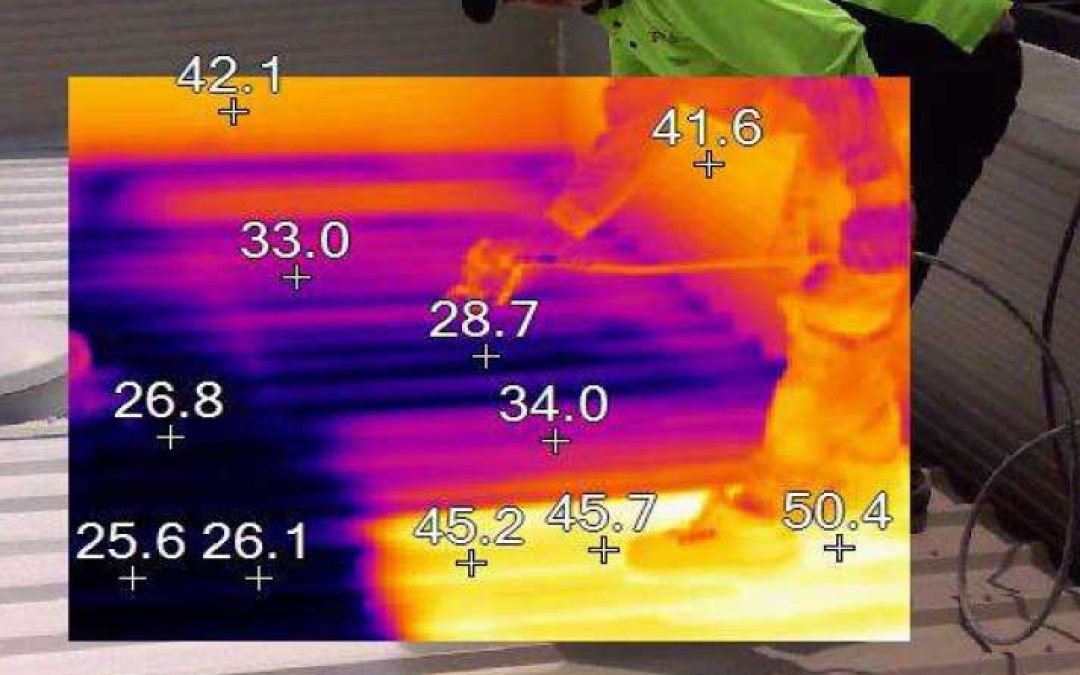

BlueScope Steel Limited is an Australian flat product steel producer that was spun-off from BHP Billiton in 2002 and it’s brand Colorbond is recognised as a leader in roofing supply industry. The Sydney based client with Colorbond roof towards the East-North side was using AC indoor unit virtually 24/7 during Australian summer time. After brief preparations and cleaning our applicators have applied a thin layer of about 0.5-0.6mm of C-COAT producing an immediate reduction of about 20oC in surface temperature and accordingly reducing a need for AC totally. We followed up with this client to find that they experienced huge reduction in electricity bill and significant improvement in indoor conditions.

by Serge Popovich | Sep 26, 2019 | News

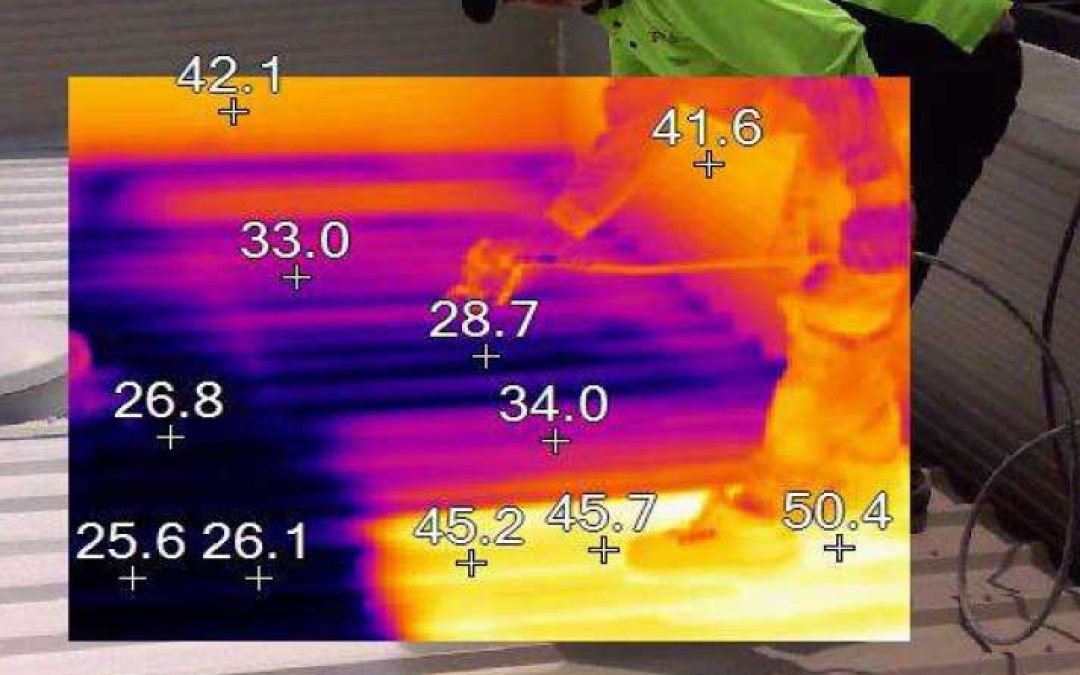

Our Korean distributor have orgnised a high level introduction of C-COAT to a major Korean tyre fanufacturer. They had the issue with continuosly replacing classic insulation over steam pipes and tyre moulds so they wanted to find if C-COAT may be suitable replacement or complimentary product for this purpuse.

During this visit our Team were able to demonstrate superior quality of our material and point to about the differences applicable to this new technology material.

If C-Coat would be applied in thin layers (0.7mm WFT and 0.5mm DFT) with spray gun in control environment, we would expect additional improvements in temperature reduction.

However, we demonstrated that when measured with classic instruments we achieved 43-58% reduction with up to 3.0mm thickness of C-COAT.

With Elcometer 319 and measuring over 20sec intervals those reductions are shown to be 65-68%.

by Serge Popovich | Jun 27, 2019 | News

The SUEZ plant has requested a “safe to touch” feature for their steem pipes t be installed in water treatment plants. The insurance claims from industrial accidents when manintence staff would accidently touch hot pipes (150-200oC) causing skin burns (temp over 58oC would cause skin burns) were a significant problem for the company. After installing a thin layer of C-COAT the staff was fully protected from accidental skin burns.

In about next 6 months SUEZ also have noticed a reduction in energy consumption at those plants and this subject is now a matter of further investiagtion where we are estimating energy savings from about 15% to 35%.

by Serge Popovich | Apr 22, 2019 | News

22nd April 2019

Pulford Air & Gas has ordered heat protection of HQ Containers used to deliver air and gas to BHP mines truck tyres. Inside of this HQ client has installed compressors and Nitro gas tanks used to fill the tyres of large mining trucks. In desert environment with scorching temperatures above 55oC our thin layer of C-COAT provided a full and long lasting protection. Previously the operators were able to work only by night time where with this application they even use those metal structures for social gathering and hiding from daylight heat