Energy Savings in Industry

Save 70% of energy loss

C-Coat saves approx. 70% of energy loss and protects equipment

C-Coat helps you comply with:

Work Health & Safety regulations

- Prevents overheating in summer and frost penetration in winter

- Prolongs service life of coated vehicles, containers, reservoirs and tanks

- Blocks condensation and eliminates destructive corrosion processes

- Protects personnel against burns

- Durability for lower maintenance

- Heat insulation of processing equipment

- Protects copper and high-temp surfaces

- Thermal insulation of pipes and fittings

- Prevents condensation and corrosion

- Decreases cost of heating at source

- Decrease in repair and service costs

- Transported substance not affected

- Oil, gas and water pipe lines protection

- Reduction of power needs

- Aesthetic appearance and compatibility

- High maintainability, no need to stop technological process while applying

- Environmentally friendly material with no waste

- Can be colour matched, suitable for large surfaces

- Considerable decrease in vibration and noise when applied to metal surfaces

Two identical mobile container offices 20-foot type with A/C units were used to compare results

The first is a standard unit and the second has C-Coat of about 1-1.5mm thick layer applied with an airless spray gun (Graco 795).

The ambient temperature was 38oC and the surface temperature was 41.5oC.

In the standard office unit, the installed A/C unit could not reduce the indoor temperature below 33oC and used about 1.0KW of electricity.

In the unit using C-Coat insulation coat, the indoor temperature was 24oC and A/C unit used about 0.6KW of electricity.

So, the addition of C-Coat achieved 40% of electricity savings and an almost 10oC cooler indoor temperature.

C-Coat Innovation

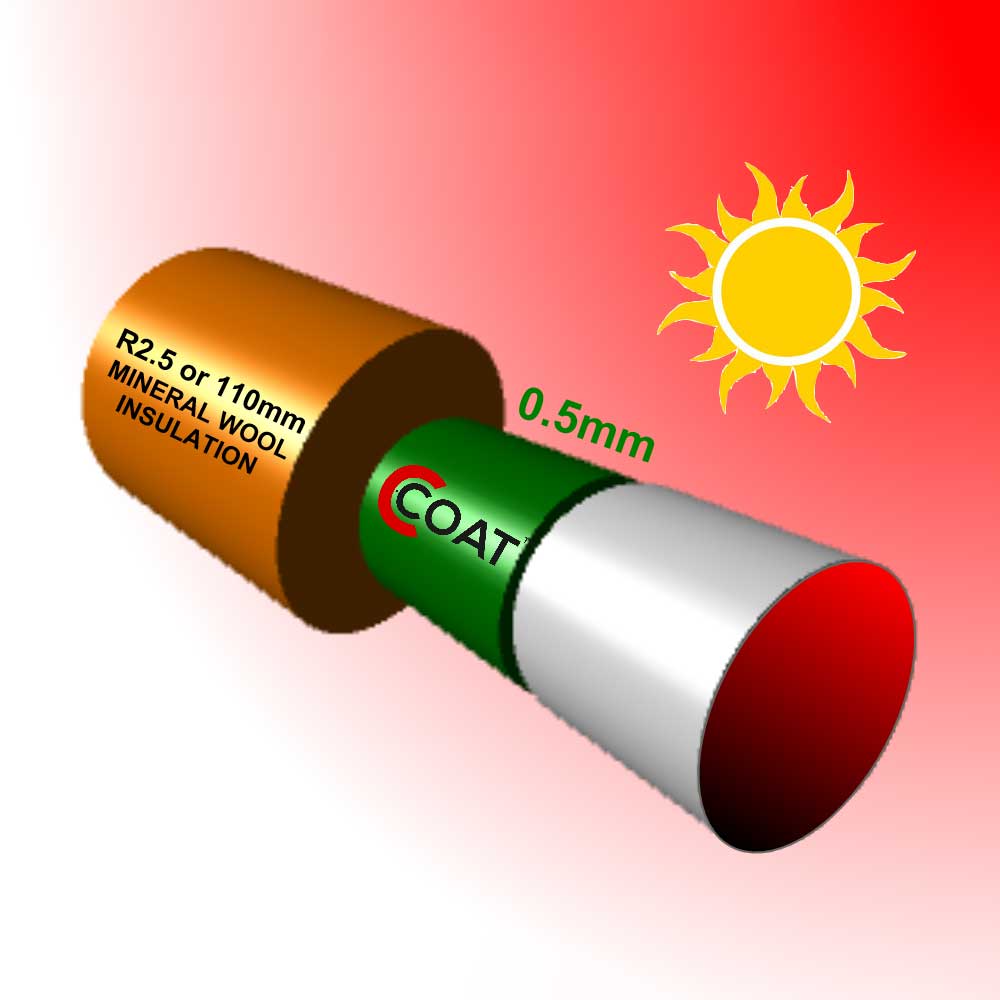

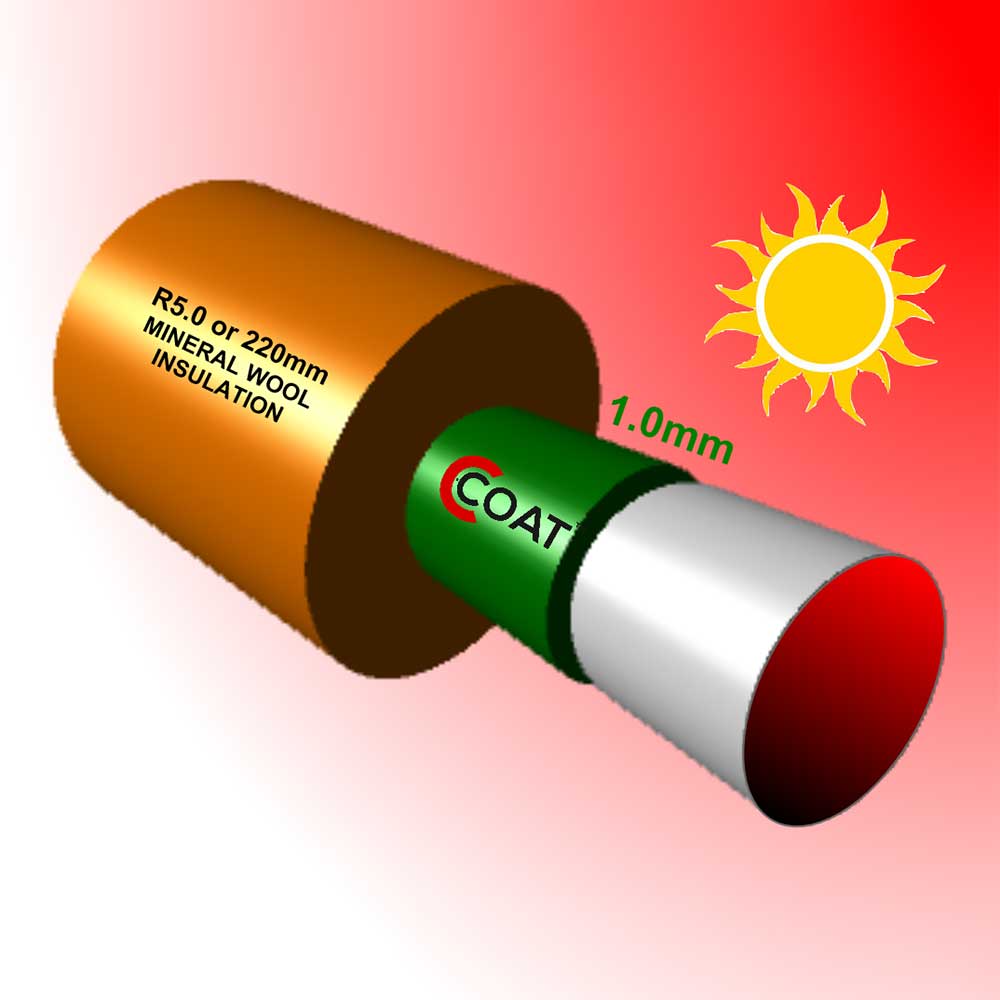

In accordance to our modelling C-Coat IP Method for various applications please find another group of popular applications of C-COAT as follows:

| Application: | FLUID TRANSFER in PIPES or BOILER VESSELS |

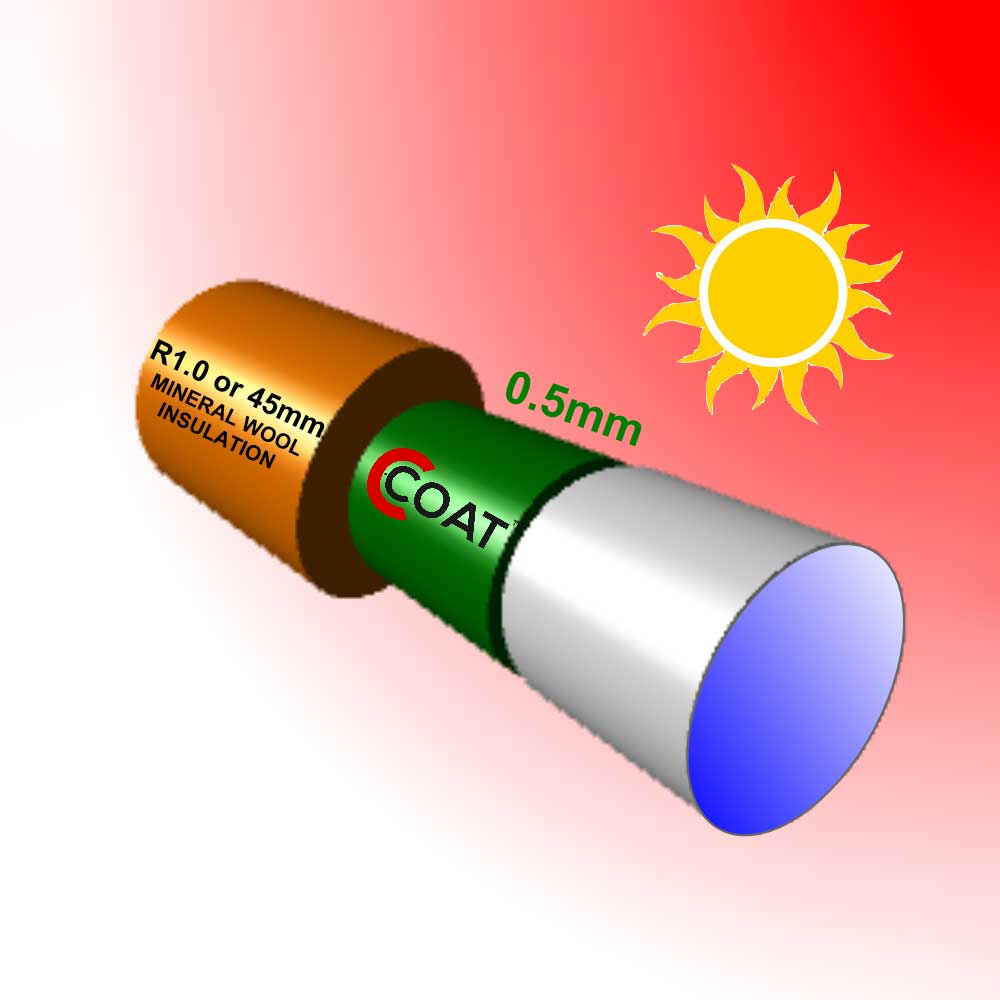

| Environment: | SUN OPEN AIR |

| Medium: | WATER OIL CHEMICALS… etc. |

| Design: | FLUID NEEDS PROTECTION FROM SUN HEAT |

| Application: | FLUID TRANSFER in PIPES or BOILER VESSELS |

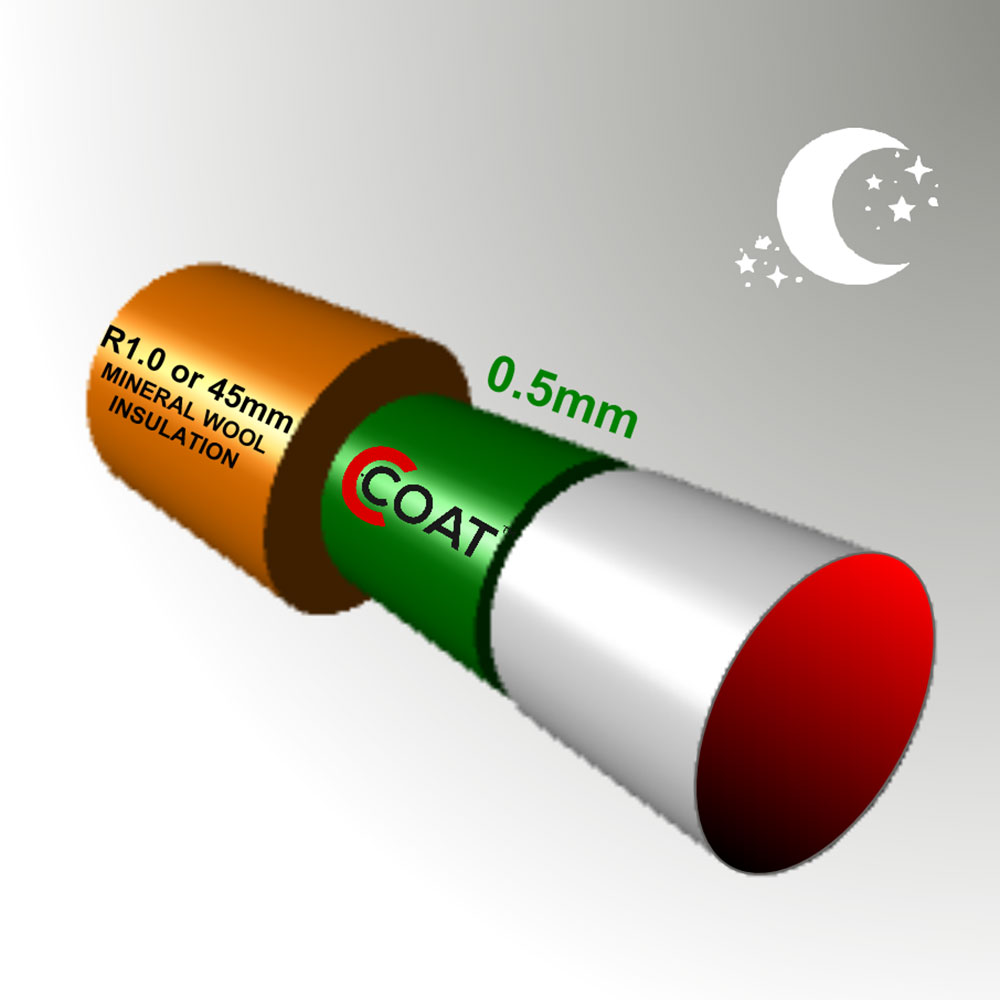

| Environment: | NO SUN OPEN AIR |

| Medium: | WATER OIL CHEMICALS… etc. |

| Design: | FLUID HOTTER than AMBIENT REDUCE LOSSES |

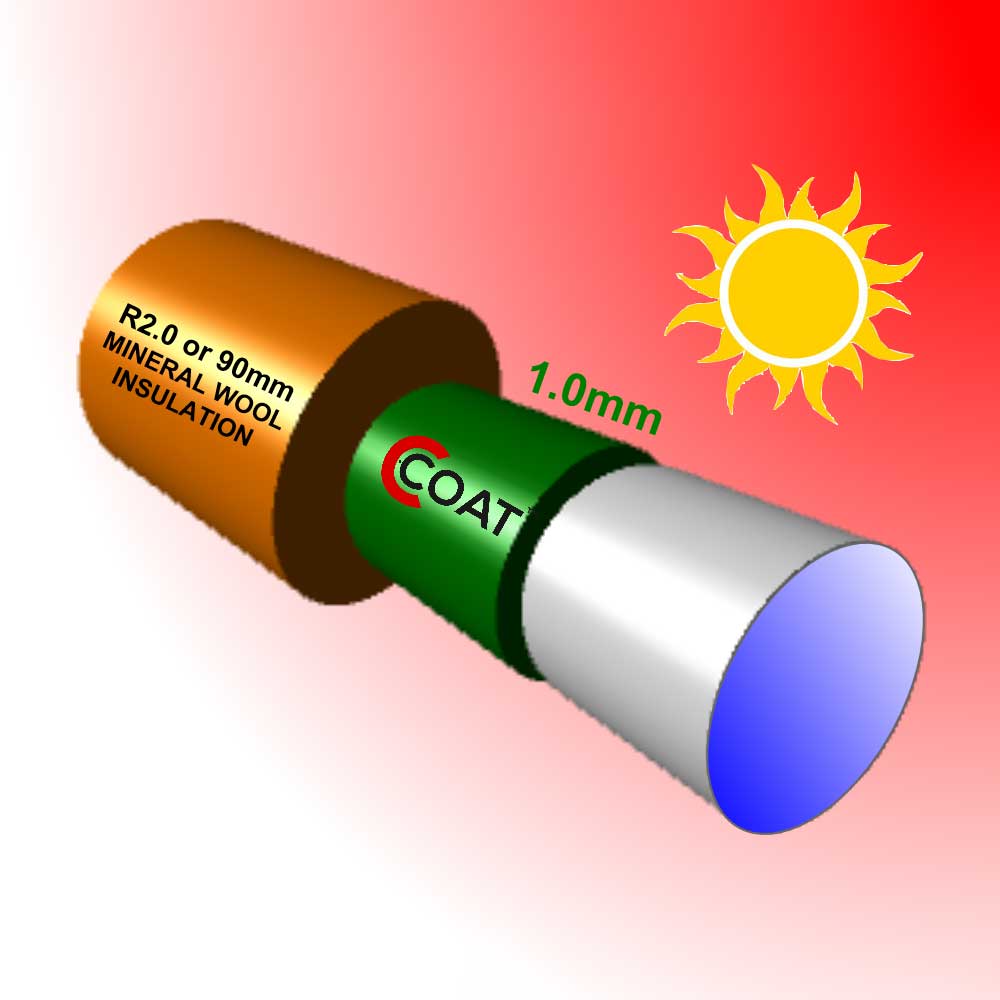

| Application: | FLUID TRANSFER in PIPES or BOILER VESSELS |

| Environment: | SUN OPEN AIR |

| Medium: | WATER OIL CHEMICALS… etc. |

| Design: | FLUID COOLER than AMBIENT REDUCE LOSSES |

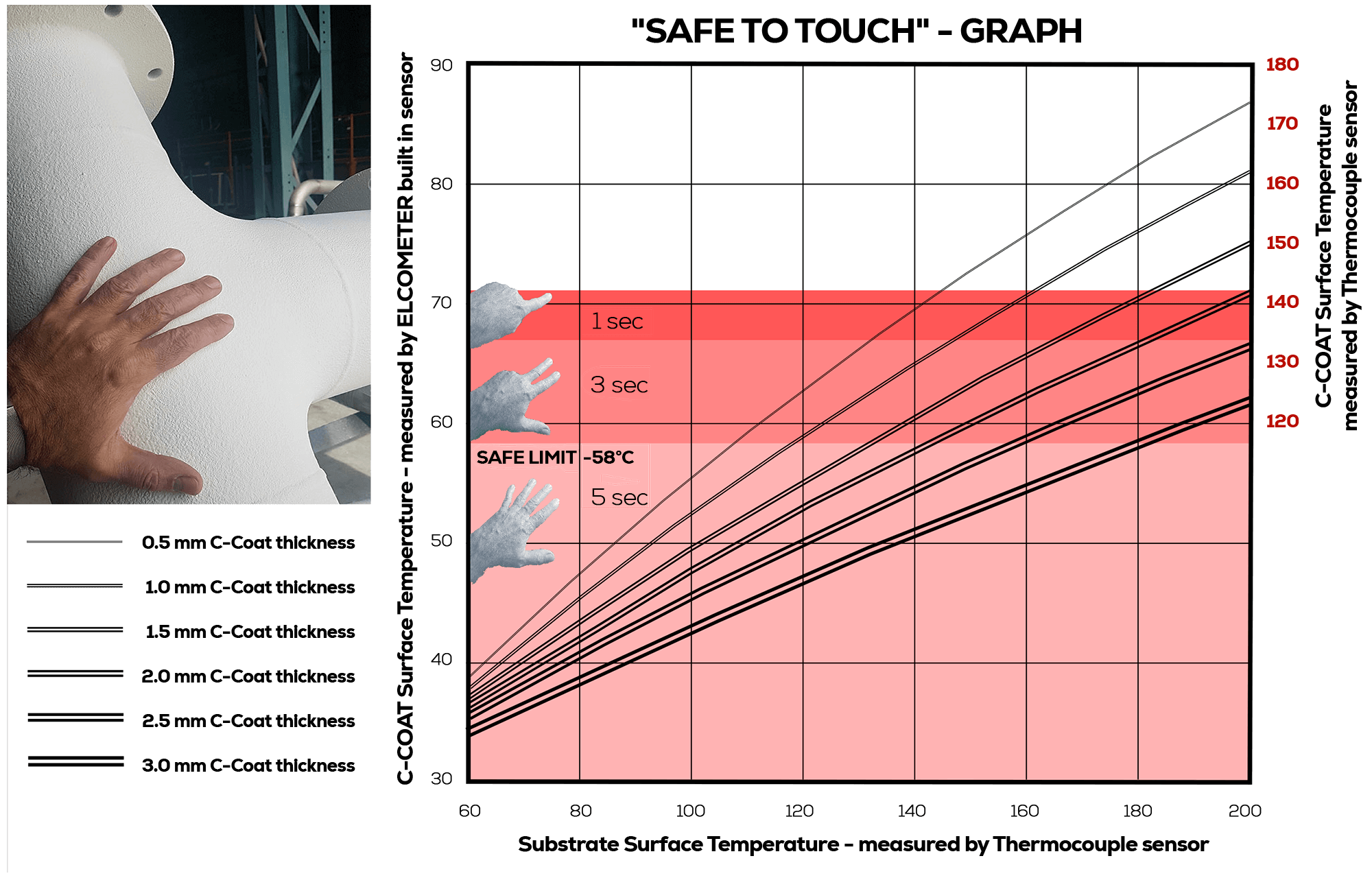

In many process plants with high heat processes in pipes or vessels the safety of the maintenance staff and visitors is very important. To prevent injuries and skin burns due to accidental contact or touch to hot surfaces you may exploit a unique feature of C-COAT that we call “SAFE TO TOUCH” feature.

Please use following graph as a guide for selecting C-COAT thickness to protect your hot surfaces. We nominated 5 sec zone (less than 58oC) as per standards so please use this zone to specify. However, in practical situations we found that most of contacts are occurring in period of 1 to 3 sec and as such he temperatures are slightly higher as shown in the graph.

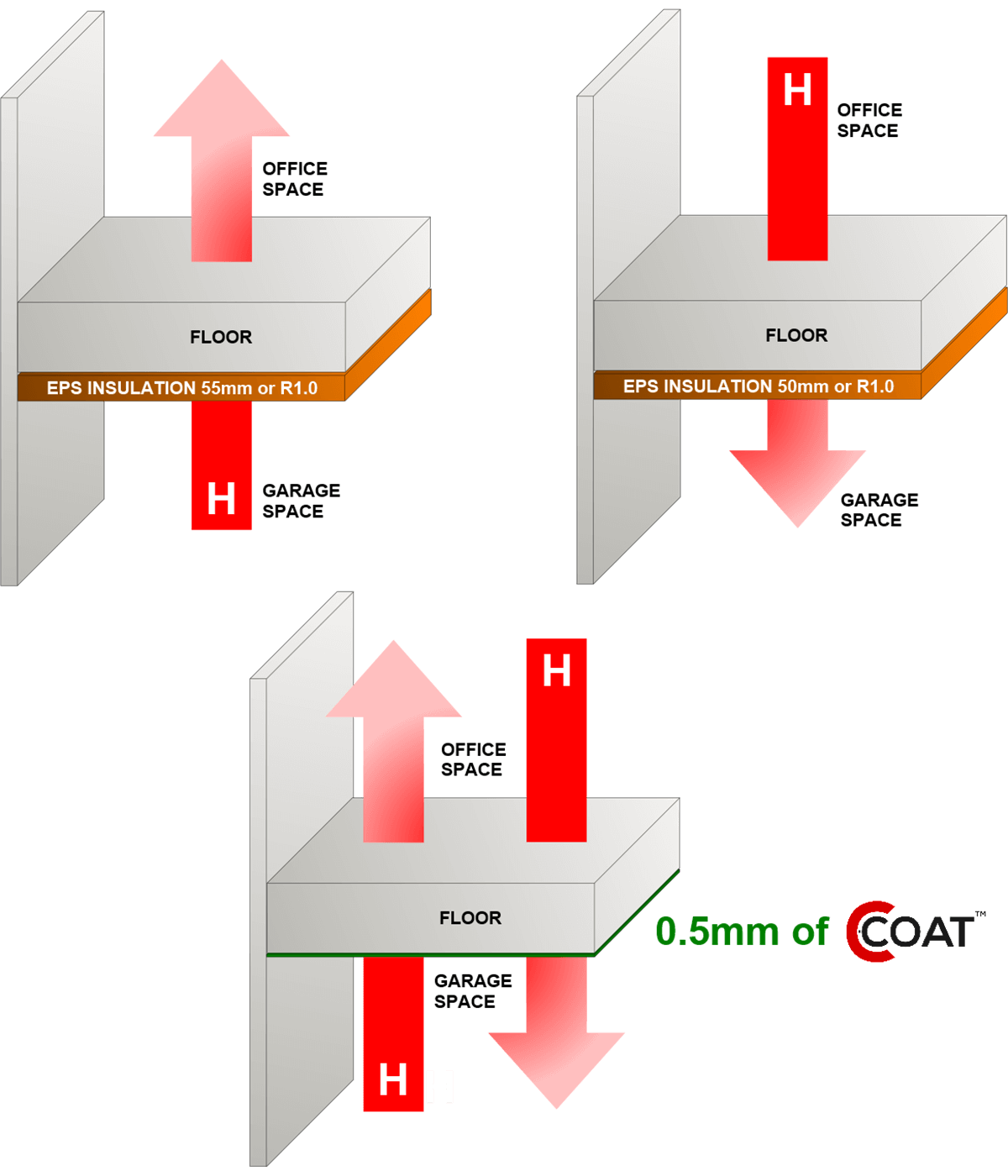

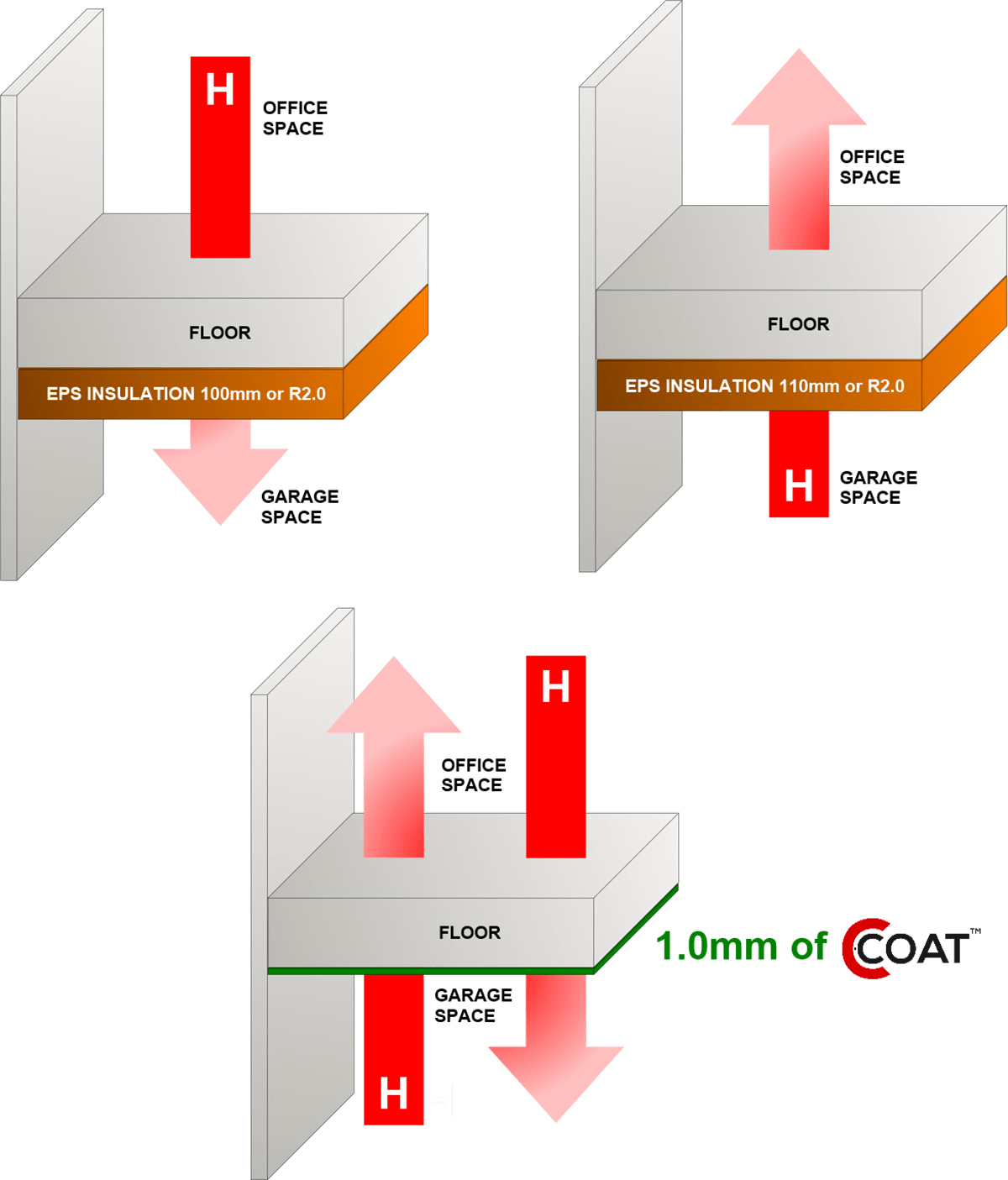

Commercial buildings are exposed to various thermal demands. However, most common request is to block the heat from lower floors (garage) to upper floors (office). As we pointed already that C-CAOT performance depends on application, environment and temperatures following diagrams are showing design modification that can be either replaced or enhanced (apply over installed insulation material) with C-COAT thermal insulating coatings thin layers.

Following is the option with R1.0 EPS insulation replaced with 0.5mm of C-COAT

|

|

|

|

NOTE: If C-COAT is to be applied over the existing EPS or mineral wool insulation, in retrofit projects, to improve insulating capacity please ensure surface preparation is done well and all loose ends replaced or repaired before spraying C-COAT.

So, applying 0.5-1.0mm of C-COAT over existing EPS or mineral wool will double or increase thermal capacity of your project.

With a vision to make the world a better place, we supply revenue positive systems to reduce energy usage & protect the environment.