C-Coat TDS & SDS

Technical Data Sheet & Safety Data Sheet

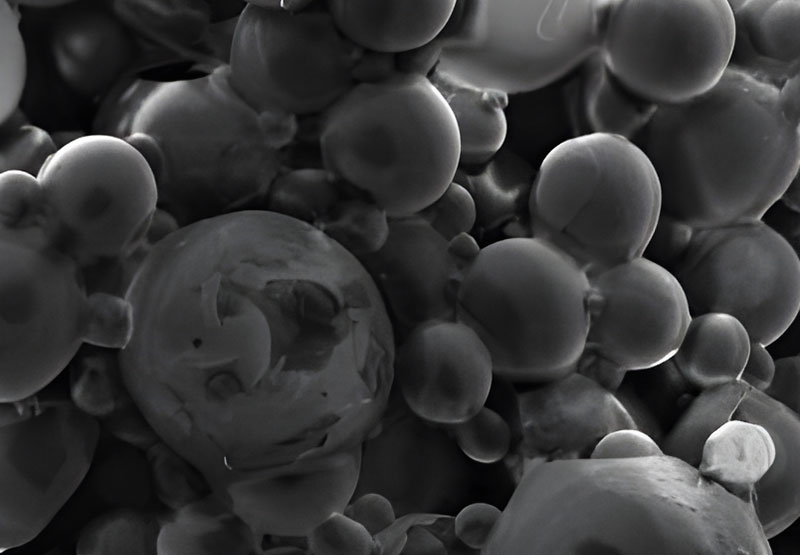

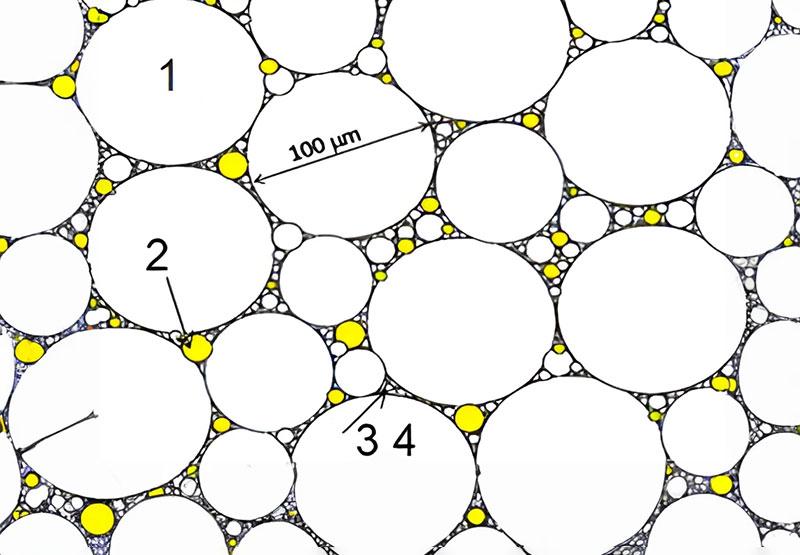

C-Coat is a liquid waterproofing and thermal insulation coating made from microscopic, ceramic balls and air filled silicon balls. The ceramic balls are suspended in water, latex and acrylic polymers mixture.

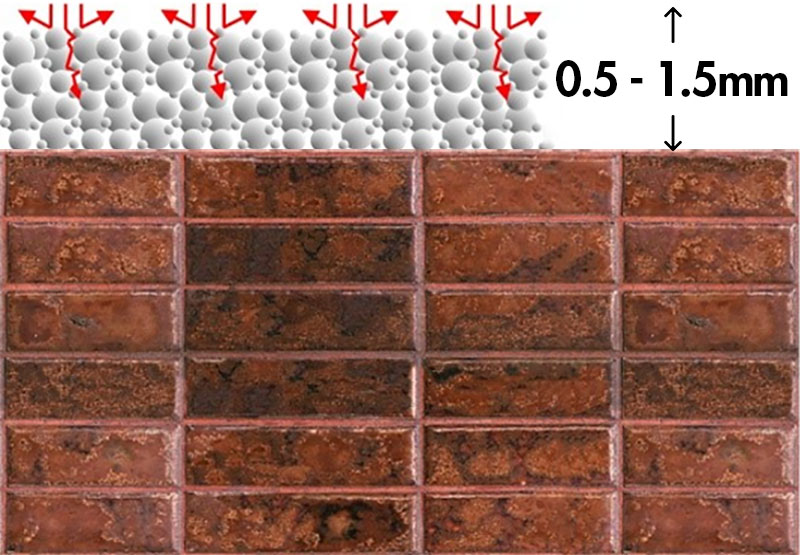

The heat transfer coefficient of C-Coat (1.29 – 2.2 W/m² K) is much lower than for other construction and thermal insulation materials (9.0-23.0 W/m² K).

The thermal insulating effect of C-Coat applied in a 1.0mm thick layer (2 x 0.5mm) gains 40% and is the equivalent of that of 100mm of rockwool or 100mm of polyurethane foam.

Applied with airless spray gun

Applied with a brush

- Highly resistant to weather conditions and temperature variations

- Highly resistant to sun damage

- Extremely low coefficient of heat conductivity: 0.0017 – 0.0030 W/mK

- Durable with 10-year warranty and expected 20-year life for outdoor use

- High degree of adhesion

Corrosion-resistant, waterproof - Can be used in conditions of up to +260°С

- Easy-to-manage application, even when plant is in operation

- Ease of repair, with only visual inspection required to find any flaws

- Resistant to mechanical damage (material flexibility >10%)

- Can be used on pipelines and objects with complicated configuration, or hard-to-reach places

- Ecologically clean and fireproof material, totally non-hazardous

- Costs and period of installation usually works 30% lower compared with traditional heat insulation

C-Coat offers around 50 layers of vacuum microspheres in a layer of 1.5mm thickness. These layers create a thermal barrier and prevent the passage. Heat flow is reflected (70%) and is partly spread (20%) so the heat flow decreases and the energy is conserved.

- Ceramic balls

- Air-filled silicon balls

- Solid acrylic balls

- Nano-TiO2 feed suspension

| MATERIAL NAME | THERMAL CONDUCTIVITY FACTOR [W/mK] |

| C-Coat | 0.0017- 0.0030 |

| Fibre insulating board | 0.048 |

| Glass wool insulation | 0.040 |

| Gypsum board | 0.170 |

| Classic insulation material | 0.035-0.160 |

| Kapok insulation | 0.034 |

| Rock wool insulation | 0.045 |

| Plastic foam insulation | 0.030 |

| DESIGNATION | CHARACTERISTIC |

| Packaging | Tight sealed plastic bucket |

| Packaging volume | 10, 20 and 100 L |

| Colour | White (RAL 9003 Signal White) |

| Coat thickness (layer) | 0.5 mm dry |

| Base | Water-based acrylic |

| Chlorides | None |

| Weight | 0.5 kg/L |

| Elongation | Above 600% |

| Transmittance | 0 |

| Hardness | Shore “A” (ASTM D2240-05) |

| Density | 249 kg/m3 (ASTM D1622-98) |

| Elasticity | 46.48 MPa (ASTM D638-99) |

| Thermal conductivity | 0.0017 – 0.0030 W/mK (ASTM C518-10) |

| Solar reflective index (medium wind conditions) | 104.85% (ASTM E1980:11) |

| UV Reflection | 100% |

| Vapour permeability | 0.003% |

| Water absorption | 0.001% |

| Tensile strength (adhesion) concrete | 1.09 N/mm (ASTM D4541-95) |

| Tensile strength (adhesion) steel | 0.81 N/mm (ASTM D4541-95) |

| Tensile strength (adhesion) brick | 1.33 N/mm (ASTM D4541-95) |

| Combustibility | Incombustible |

| Application temperature tolerance | -20°С to +250°С |

| Operation temperature tolerance | -60°С to +400°С |

| Drying time to degree 3 at + 20°C | 60 min |

| Transportation temperature | +5°С to +45°С |

| Resistance of a covering to impact of difference of temperatures -40°C up to +180°C | No changes |

| Application method | Airless sprayer, brush, roller |

| Abrasion resistance | High |

| Shelf-life of the material | Up to 1 year from date of manufacture |

| Service life | Thermal engineering – 15 years. Protecting substrate – > 20 years |

| Top-coating for specific application | Contact supplier |

With a vision to make the world a better place, we supply revenue positive systems to reduce energy usage & protect the environment.